Aerospace

DEMGY Normandie DEMGY Atlantique DEMGY Făgăraș DEMGY Chicago DEMGY Paris DEMGY EIS DEMGY PacificThe aeronautics, space and defence sectors need to provide advanced and varied technical solutions. Quality and reliability are essential values.

DEMGY is able to support its customers from initial design and co-design of parts and subassemblies through to their actual manufacture. We can create prototypes and then proceed to the manufacture in small, medium or high volume.

Our expertise

The expertise of DEMGY is constantly developing in the implementation of high-performance engineering polymers and composites for aeronautics and aviation. Our technologies are perfectly adapted to the treatment of these composite materials. Our expertise in the machining allows us to model high performance plastics such as Vespel®, of which we are authorized distributors of the DuPont ™ Group for France.

Our workshops and the competence of our teams allow the manufacture of high precision parts, thanks to our know-how in injection, compression, forming, thermoforming, low pressure moulding and surface treatment. We also take action in the assembly (boiler making, welding, gluing, plastic welding). In addition, we offer assembly (forming, welding, glueing, plastic welding) along with a full range of decoration processes.

Reference applications and Components

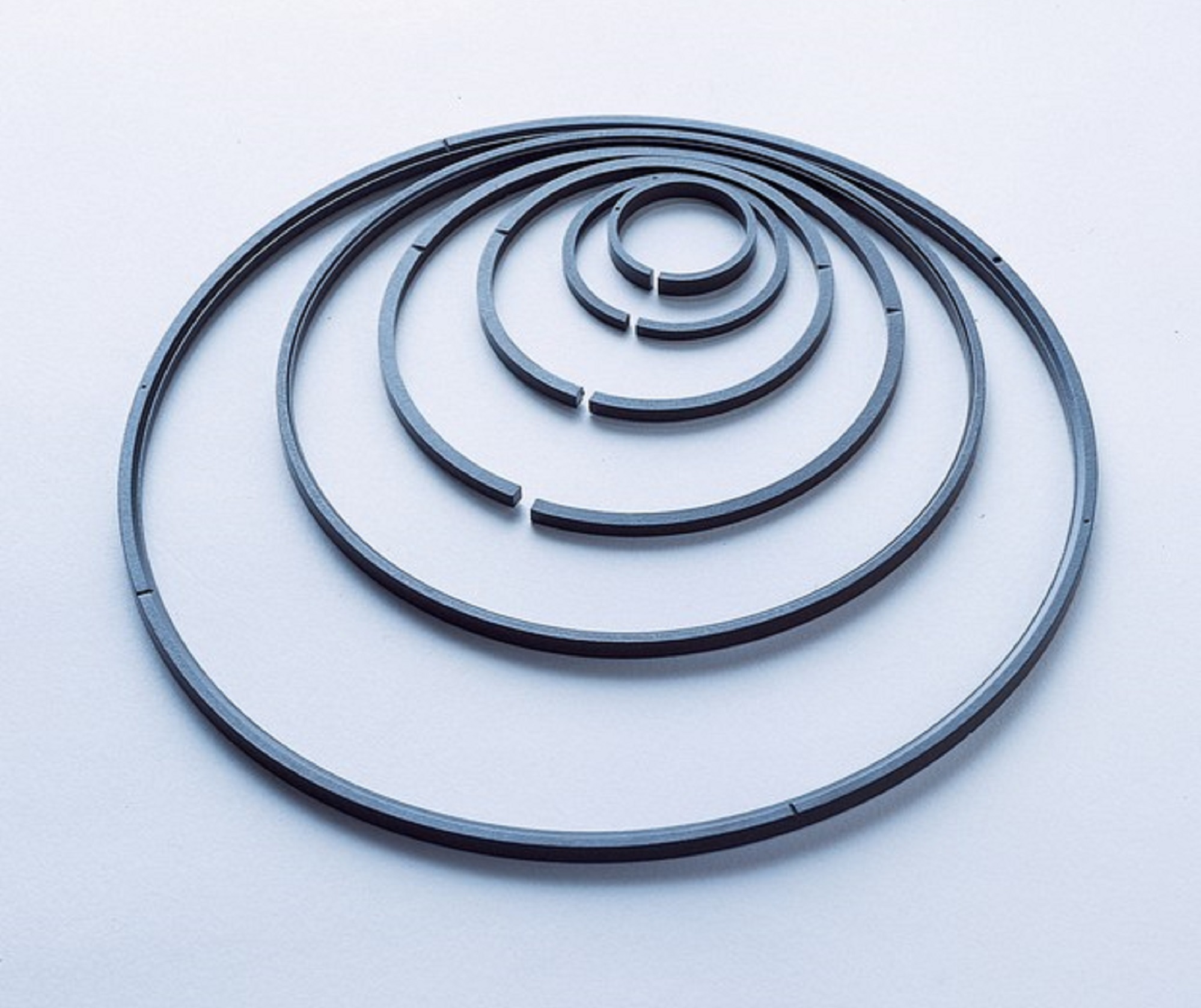

Our technology finds opportunities in many reference applications, critical components such as wear and friction parts, bearings, bushings, segments, bearing cages, or sealing parts (seals, bellows, seats and valve bodies).

Whether hot or cold area components, cryogenics, our know-how covers all conditions. In the same vein, all fastening components (clips, screws, nuts, clamps, sleeves, washers) and components for instrument panel (front display, diffuser, light guide and buttons) can benefit from our experience. Our area of expertise in metallization and surface treatment is in the electrolytic metallization of metal and plastic components. In the latter case, we offer high performance polymers such as PEEK and ULTEM.