Research & Development

We believe that our company longevity is guaranteed by this approach of constant research of techno-economic solutions always closer to customer and consumer needs.

Whether assembled for a customer or for internal needs, each project can go through R&D steps.

These R&D steps are provided by 8 people exclusively dedicated to non-standard issues, i.e. when the process, raw materials, tools are not on the shelf.

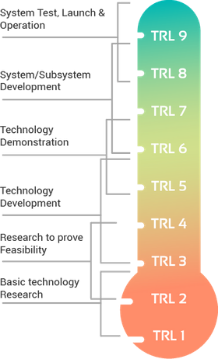

At TRL level (Technology Readiness Level) scale, we work on projects ranging from level 4 to level 9, a brief description below.

| TRL | Description |

|---|---|

| 1. Observed and reported basic principles | Lower level of technological maturity. Scientific research is beginning to translate into applied research and development. Examples may include paper studies of the basic properties of a technology. |

| 2. Concepts or applications of technology formulated | The invention begins. Once the basic principles are observed, practical applications can be invented. The application is speculative and there is no evidence or detailed analysis to support this hypothesis. |

| 3. Critical Function Analyzed and Experienced or Product Characteristic Evidence | Active research and development is initiated. This includes analytical studies and laboratory studies to physically validate the analytical predictions of separate technology elements. Examples include components that are not yet integrated or representative. |

|

4. Laboratory validation of the component or artifact produced |

The basic technological components are integrated to establish that all parts work together. It is a "low fidelity" compared to the final system. Examples include the "ad hoc" integration of equipment in the laboratory. |

|

5. Validation in a significant environment of the component or artifact produced |

The fidelity of the technology increases significantly. The basic technological components are integrated with reasonably realistic elements so that the technology is tested in a simulated environment. Examples include the "high fidelity" integration of components in the laboratory. |

|

6. Demonstration of system/subsystem model or prototype in a significant environment |

The representative prototype model or system (well beyond the artifact tested in TRL 5) is tested in a significant environment. It represents a major advance in the proven maturity of a technology. Examples include testing a prototype in a "high fidelity" laboratory or in a simulated operating environment. |

|

7. Demonstration of prototype system in operational environment |

Prototype in a planned system (or about to be). Represents a major advance over TRL 6, requiring the demonstration of a prototype system in an operational environment, such as an aircraft, vehicle... Examples include prototype testing on a test aircraft. |

|

8. Complete real system qualified through tests and demonstrations |

Evidence has been provided that the technology works in its final form and with the expected conditions. In most cases, this TRL represents the end of the development of real systems. Examples include testing the development and evaluation of the system to determine if it meets the design specifications. |

|

9. Proven real system through successful operations/missions |

The actual application of the technology in its final form and in mission conditions, similar to those encountered in operational tests and evaluation. In any case, this is the end of the last aspects of problem fixes (bug fixing) in the development of real systems. Examples include the use of the system under operational mission conditions. |

Our R&D department aims to:

- Shape the company future, working on the technologies/materials/processes of tomorrow: that means going through technology intelligence, participation in scientific conferences and technical fairs, realization of collaborative projects (with IRTs) and investing capital stock on R&D projects in order to work on our customers’ future needs

- To go in hand with our units service projects in the development of innovative products, by providing expertise in the field of structural calculation, thermal calculation, composite materials or high-performance polymers

- Developing innovations on current technology/tooling to reduce production costs and meet current or future economic needs of our customers

By incorporating all of our plastics and thermoplastic composites experience, DEMGY group is able to add value to customers’ brand through reduction of mechanisms, design and manufacture of high-performance plastic parts and thermoplastic composites, which replace metal, function integration to design multi-material product and process.

Indeed, plastics and thermoplastic composites have undeniable advantages:

- Weight reduction

- Integration of functions

- Freedom of design-miniaturization

- Reduction of post-operations

- Increased mould life

- Regulations

- No corrosion

- Appearance and decoration

- More flexible implementation process

- Reproducibility of the process

- Cycle time reduction

- Recyclability (to a certain extent)

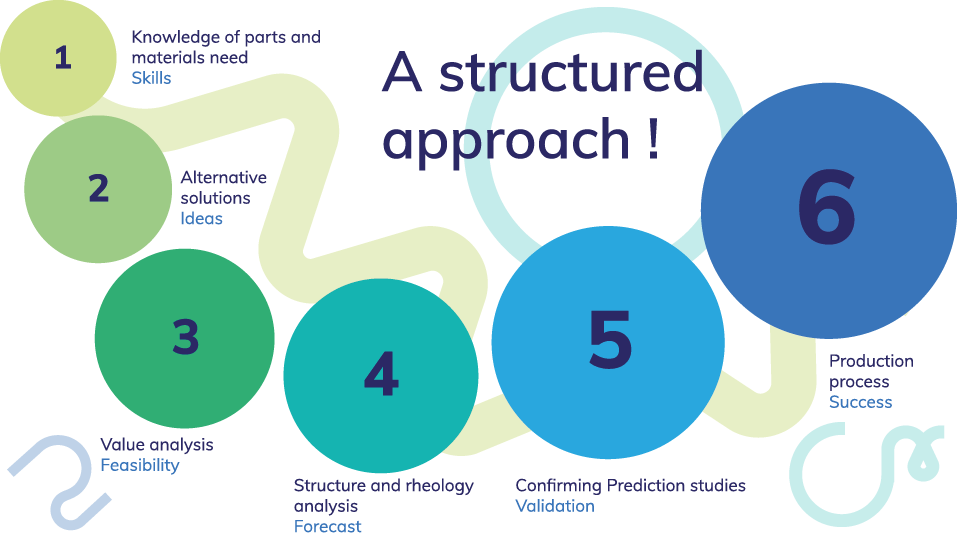

The R&D version DEMGY group, a structured approach.

Each R&D project is therefore carried out through 6 important stages:

Stage 1: meeting and exchanging with the client and understanding his strategy to define his need or its specifications and the signature of a confidentiality agreement (NDA-non disclosure agreement)

Stage 2: DEMGY group proposal:

- Part, subset or product concept and design

- Possible raw materials or to be created

- Possible transformation process or to be created

- Planning and estimated costs based on different options

Stage 3:

- Feasibility study of selected solutions

- First material transformation tests for validation of the feasibility

- More precise definition of the budget necessary for development or even the first estimation of single part average price

- Validation of the DEMGY group proposal if in line with the customer's techno-economic interests

- Client validation, development contract and collaboration agreement

Stage 4: Thermo-mechanical tools study, rheological analysis, mechanical characterization of test specimens (if necessary)

Stage 5: validation of the part feasibility by the realization of prototype tools and parts or creation of a 3D plan with prototype manufacturing in 3D to launch in additive production

Stage 6: technical solution industrialization