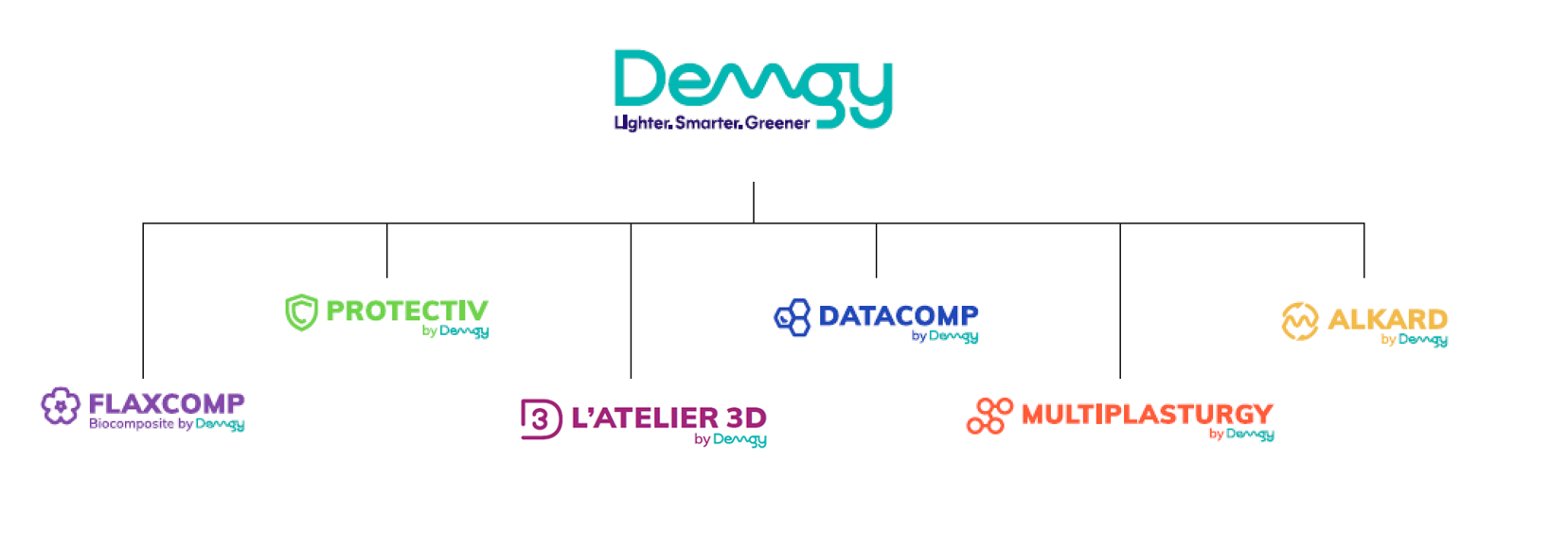

DEMGY : A large corporate Family

DEMGY is a large family encompassing several subsidiary brands. What do they have in common? Their expertise, know-how and a commitment to a greener world!

Multiplasturgy ®

![]() Multiplasturgy is our core business, what DEMGY did from its very origins. What is the concept? The mastery of innovative industrial technologies and an advanced and recognized knowledge of numerous plastics, high-performance polymers and composites.

Multiplasturgy is our core business, what DEMGY did from its very origins. What is the concept? The mastery of innovative industrial technologies and an advanced and recognized knowledge of numerous plastics, high-performance polymers and composites.

Our know-how in plastic processing enables us to cover a wide spectrum of applications: injection and micro-injection, high precision machining, forming, thermoforming and stamping, design and manufacture of molds, tools and parts, processing, decoration and assembly, metallization, creation of bio-composites, etc. It’s more than just plastics processing, it's multiplasturgy!

Flaxcomp ®

Flaxcomp manufactures a 100% biodegradable and biosourced biocomposite! What does it contain? It is made from flax fibers and corn starch resin. Designed in partnership with Terre de Lin, this biocomposite personifies the green industry of tomorrow.

Flaxcomp manufactures a 100% biodegradable and biosourced biocomposite! What does it contain? It is made from flax fibers and corn starch resin. Designed in partnership with Terre de Lin, this biocomposite personifies the green industry of tomorrow.

The fiber is light, tough, rigid and environmentally friendly. Flaxcomp also absorbs vibrations and has excellent sound insulation properties. This Demgy innovation replaces the synthetic fibers and chemical resins usually used in industry.

Automotive parts, sports equipment, disposable tableware, train parts, etc. Flaxcomp is versatile and will suit all your projects, even the most complex!

Protectiv ®

Protectiv, our subsidiary brand, manufactures sustainable protective equipment that is 100% made in France. It is made from plant-based materials that care for the environment. Breathing masks, plexiglass screens, hands-free door openers, protective visors and more. Everything you need to protect yourself and others!

Protectiv, our subsidiary brand, manufactures sustainable protective equipment that is 100% made in France. It is made from plant-based materials that care for the environment. Breathing masks, plexiglass screens, hands-free door openers, protective visors and more. Everything you need to protect yourself and others!

The brand genesis took place during the Covid-19 crisis, as a way of participating in the national effort. It was the "Visors of Hope" operation that prompted Demgy to manufacture visors using 3D additive manufacturing and to donate them to nursing staff.

No more disposable equipment: with Protectiv, masks are reusable and sometimes even dishwasher safe. Break free of the surgical masks that litter the streets, choose non-polluting protection, made with respect for the nature we care about!

Atelier 3D

Atelier 3D (the 3D workshop) is an industrial revolution in its own right. What’s the concept? 3D printing all your parts, saving you time and money. Our HP Jet Fusion 4200 machine uses polyamide 11 Rilsan®, a natural material made by Arkema from castor oil. DEMGY also has an EOS P 810 laser sintering machine for EOS HT-23 material.

Atelier 3D (the 3D workshop) is an industrial revolution in its own right. What’s the concept? 3D printing all your parts, saving you time and money. Our HP Jet Fusion 4200 machine uses polyamide 11 Rilsan®, a natural material made by Arkema from castor oil. DEMGY also has an EOS P 810 laser sintering machine for EOS HT-23 material.

This material produces lightweight and highly impact-resistant parts. Their properties in terms of ductility and elasticity are far superior to those of polyamide 12.

3D additive manufacturing makes it easy to produce prototypes of all kinds to the most complex designs. Give way to your wildest ideas: Atelier 3D makes them come true! Above all, 3D additive manufacturing allows you to produce your parts very quickly, at a much lower cost than traditional manufacturing methods, regardless of the number of units to be produced.

Find out more about the 3D workshop

Datacomp ®

Datacomp is an interactive, simple, complete and comparative database developed by DEMGY. It enables you to freely consult a wealth of information about our polymers and resins. Datacomp answers all your questions about ABS, aluminum, polystyrene or polyamide!

Datacomp is an interactive, simple, complete and comparative database developed by DEMGY. It enables you to freely consult a wealth of information about our polymers and resins. Datacomp answers all your questions about ABS, aluminum, polystyrene or polyamide!

Datacomp is very easy to use: simply type in the abbreviation or name of the material you wish to consult, select the one you are interested in from the list and consult the detailed technical data sheet! If you wish, you can even compare the different properties of the materials.

Alkard

Alkard is a microwave absorber developed by DEMGY. It enables radio wave receivers carrying data to pick up exactly the desired frequency. Make electromagnetic compatibility issues a thing of the past! Mainly used for defense applications, Alkard is also relevant for many other sectors. It can be used as a waveguide, coaxial cable or in free space.

Alkard is a microwave absorber developed by DEMGY. It enables radio wave receivers carrying data to pick up exactly the desired frequency. Make electromagnetic compatibility issues a thing of the past! Mainly used for defense applications, Alkard is also relevant for many other sectors. It can be used as a waveguide, coaxial cable or in free space.

There are several types of Alkard and each of them can be adapted to one of your needs. It is a state-of-the-art innovation, the result of over 20 years of research. The polymers used are made up of epoxy resin, iron, graphite or additives depending on the application.