Thermoforming

DEMGY Normandie DEMGY Atlantique DEMGY Paris DEMGY EISDEMGY know-how in plastic thermoforming

Thermoforming, a key expertise at DEMGY

What is thermoforming?

Thermoforming is a process that consists in heating a sheet of thermoplastic material to give it a defined shape using a mold. At DEMGY, this technique is optimized thanks to modern equipment and recognized expertise in the transformation of technical and high-performance polymers.

The advantages of thermoforming at DEMGY

- Production flexibility

Ideal for small and medium production runs, thermoforming enables us to process parts of all sizes, from thin (< 1 mm) to thick (> 8 mm).

- Cost control

Thanks to economical, durable tooling, thermoforming offers excellent value for money for the production of complex or customized parts.

- Precision and versatility

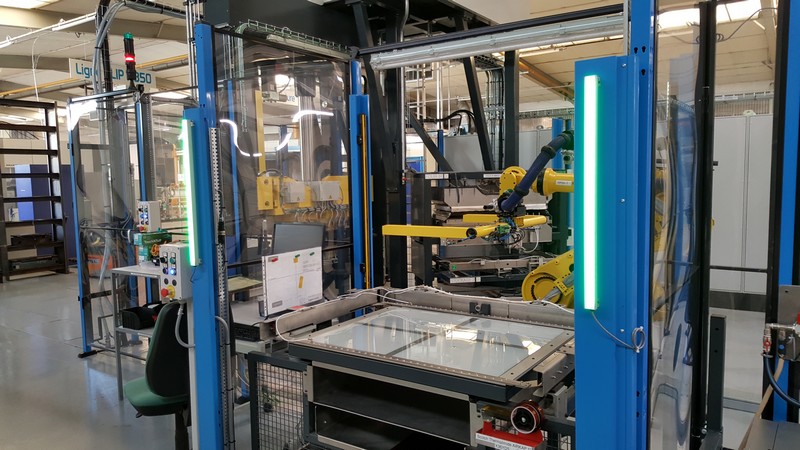

DEMGY's sophisticated equipment and routing robots guarantee enhanced precision and the ability to produce parts with the most complex shapes, while adapting to the specific requirements of each industrial or consumer goods sector.

Materials used for thermoforming

At DEMGY, we process a wide range of technical polymers and thermoplastic composites:

- Commodity polymers: PE, PP

- Technical polymers: ABS, PC, Kydex

- High-performance polymers: Ultem®, PEEK

- Thermoplastic composites: for demanding applications

Our thermoforming equipment

To guarantee optimum production, DEMGY has :

- 6 thermoforming machines, including one for thermopressure

- 10 5-axis CNC centers, dedicated to trimming and machining

- 4 compression presses, with capacities ranging from 80T to 500T

- 2 linear transitic ovens, for optimum thermal control

Industrial sectors concerned by thermoforming

Thermoforming is an extremely versatile solution, used in many industrial sectors to manufacture technical and customized parts. Thanks to its expertise, DEMGY is able to meet the specific requirements of each field by supplying robust, lightweight, high-performance parts. Here are just a few examples of applications:

- Motorsports :

DEMGY works with prestigious brands such as Alpine, supplying thermoformed components for motorsport applications. Thermoforming enables the production of lightweight yet strong parts, essential for reducing vehicle weight while maintaining optimum performance. Parts produced include interior elements and specific panels that meet stringent safety and strength requirements.

- Aeronautics:

In the aerospace sector, DEMGY supplies complex parts such as filter housings. These components must meet rigorous safety and performance standards, with materials capable of withstanding high temperatures and mechanical stress.

- Rail :

DEMGY also supplies seats and backrests for the rail industry. These parts are designed to combine comfort, safety and durability. Thermoforming enables us to produce components that are ergonomic and resistant to rail transport conditions, while offering flexibility in the shapes and sizes required.

- Medical :

In the medical field, DEMGY produces thermoformed racks that are used for medical devices. These parts are designed to ensure patient safety while complying with strict health standards. Thermoforming enables the creation of lightweight, resistant and easily sterilizable components, while maintaining competitive costs for the production of limited series or prototypes.

- Sports & Leisure:

Thermoforming is also used to manufacture components for Bonzini foosball tables. For example, ball return chutes are made using this technique, enabling the production of parts with complex designs and precise shapes. This process is ideal for guaranteeing the durability and aesthetics of components used in sports equipment.

- Transport and industrial vehicles:

In the transport sector, particularly for industrial and agricultural vehicles such as those made by CLAAS, DEMGY offers solutions for interior linings and structural components. Thermoforming enables the manufacture of light, resistant parts that contribute to improving vehicle performance, while optimizing the use of materials and reducing production costs.

Why choose DEMGY for your thermoforming projects?

When you choose DEMGY, you benefit from proven know-how and recognized expertise in plastic thermoforming. The company combines technological innovation, mastery of technical materials and rapid production to offer tailor-made solutions for every project.

DEMGY positions itself as a trusted partner to meet your needs, whether they concern small series, complex parts or applications requiring advanced materials. It also means choosing the supplier who can offer you the technology best suited to your technical and economic constraints, from among our range of process solutions such as injection molding, additive manufacturing etc...