Injection

DEMGY Normandie DEMGY Atlantique DEMGY Frasne DEMGY Făgăraș DEMGY Chicago DEMGY Deva DEMGY Paris DEMGY EISAt DEMGY, we offer specialized expertise in plastic injection molding, providing tailor-made solutions to meet our customers' most demanding needs. Thanks to our know-how and state-of-the-art equipment, we offer a wide range of services, from the industrialization of the product to mass production.

What is injection?

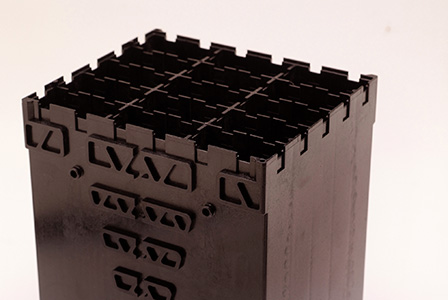

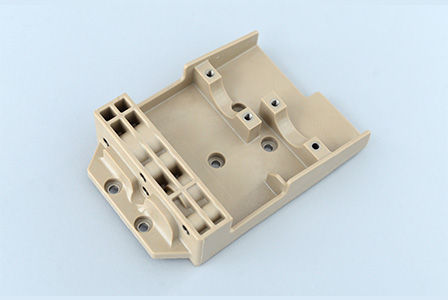

Plastic injection molding is a mold-based production process. Plastic injection takes place as follows: the material is melted and injected into a mold, where it cools and the products are extracted. Plastic injection molding enables the rapid, continuous manufacture of large volumes of parts in a wide range of complex shapes.

Production process

This plastic injection production process is designed to guarantee optimum quality and efficiency at every stage. From mold design to the manufacture of finished parts, we apply rigorous standards to meet our customers' specifications.

At DEMGY, the use of robotized and automated systems in our plastic injection processes is a major strength, enabling us to remain at the cutting edge of technology and efficiency.

Our injection molding machines are equipped with sophisticated robots that do much more than simply mold parts; they enrich our production chain by integrating additional post-injection operations. These robots perform tasks such as component assembly, quality control to ensure product compliance with the most stringent standards, marking to ensure traceability, and final packaging ready for shipment.

This advanced automation enables DEMGY to significantly reduce cycle times while improving product quality and precision, thus offering significant added value to our customers and strengthening our competitiveness in the market.

Discover the different materials processed :

- Injection molding of thermoplastics :

Our thermoplastic injection molding process uses polymers that can be heated and cooled to create parts that are easily recyclable, as they can simply be re-molded and re-injected. Ideal for a variety of applications requiring high flexibility and durability.

- Injection molding and compression molding of thermoset materials :

Injection molding of thermoset materials involves the use of polymer materials that harden irreversibly after processing. Unlike thermoplastics, these materials cannot be reprocessed or recycled after their initial shaping.

This process offers significant advantages, including excellent dimensional stability, high resistance to heat and chemicals, and durability. Parts made from thermoset materials are commonly used in environments where strength and reliability are paramount, such as the automotive and aerospace industries. (Electrical insulation)

- Overmolding :

Our metal insert overmolding technique enables additional functionality to be added to existing parts by injecting a plastic material onto them. This method offers great design flexibility and enables mechanical or electrical performance to be improved locally. It is also possible to overmold other types of insert (textile or metal filters, for example).

- Bi-material injection moulding :

With our bi-material solutions, we can combine two different materials in a single part to achieve unique properties and innovative designs. This technique offers great versatility and opens up new design possibilities.

For example, it is possible to :

- Combine flexible and rigid materials to achieve sealing functions.

- Combining materials with complementary technical and aesthetic performance.

- Achieve natural selectivity for metallization post-treatments such as chromium plating.

- Gas injection :

This technology makes it possible to incorporate a reinforcement and stability function, essential for parts with high strength and dimensional requirements.

What are the advantages of plastic injection molding?

Plastic injection molding offers a host of advantages, including high dimensional accuracy, the ability to produce complex parts, rapid production and increased profitability for large production runs.

What's more, the diversity of materials used and the possibility of integrating additional elements make plastic injection molding a versatile and durable manufacturing option.

Plastic injection also makes it possible to combine distinct properties by integrating two different materials in a single product. This functional integration offers exceptional design flexibility, enabling engineers to create parts with unique characteristics.

For example, by combining polycarbonate for its transparency and impact resistance with polyamide for its heat resistance and durability. It is possible to produce parts for electronic equipment that combine protection and aesthetics.

Application Areas

Our plastic injection services are widely used in a variety of industrial sectors, including automotive, medical and many others. Whether for technical components, aesthetic parts or everyday consumer products, we're equipped to meet every requirement.

Commitment to Quality and Innovation

At DEMGY, quality is at the heart of everything we do. We are committed to providing the highest quality products while remaining at the forefront of innovation. Our team of qualified experts works closely with our customers to understand their needs and offer tailor-made solutions that exceed their expectations.