Thermoplastic Composites and Stamping

DEMGY Normandie DEMGY Atlantique DEMGY EISDEMGY, expert in thermoplastic composites, can manufacture and transform your most complex composite materials, quickly and at a controlled cost. Stamping, thermocompression, hybrid process... Discover all our technologies!

Our expertise:

- Stamping of consolidated thermoplastic composite blanks

- Thermo-compression of thermoplastic composite fabrics

- Hybrid Process Stamping or thermocompression then overmolding by plastic injection

Composite, a material made to measure

What is a composite material? It is an assembly of two or more immiscible materials, generally composed of a matrix and a reinforcement. Nature is full of composite structures, such as wood or shells.

The matrix of a composite material is its base. It gives it the desired appearance and shape, while transferring the mechanical forces to the reinforcement. By complementarity, the latter represents the reinforcement of the new material and supports most of the constraints which are imposed to it, thanks to the protection provided by the matrix. It can be, for example, glass, carbon, or basalt fibers or even vegetable fibers, such as flax or hemp.

Composite materials have many advantages: they have characteristics that the two materials alone do not have. Depending on your specifications (mechanical performance, chemical resistance, working environment, weight, target price), we can advise you on the choice of matrix and reinforcement.

Shaping of thermoplastic composites

Stamping, thermocompression, hybrid process... DEMGY offers you its expertise in the transformation and shaping of thermoplastic composite materials

Stamping of thermoplastic composite

The stamping of thermoplastic composites consists in shaping the material under a heated press. This process allows us to control the industrialization of these innovative materials with high-end technical characteristics while controlling manufacturing times and costs.

Where traditionally the material is processed and then shaped, thermoplastic composite stamping performs all tasks simultaneously for substantial time and manufacturing savings. More technically, thermoplastic composite stamping combines heating, press transfer, pressing and finally cooling of the material in the same time frame.

DEMGY has a fully automated line for stamping your products. Thus, you gain in efficiency, speed, and productivity!

| Certification | Title |

|---|---|

| AIPS 01-02-005 | Preparation of holes in Fibre Reinforced Plastic (FRP) and Hybrid Materials |

| AIPS 03-02-020 | Manufacturing of monolithic parts with thermoplastic material |

| AIPS 03-07-002 | Machining of Fibre Reinforced Plastic (FRP) components |

| AIPS 05-05-009 | Preservation of cut edges of carbon fibre composite parts to prevent galvanic corrosion on attached metal parts |

| AITM 6-4005 | Ultrasonic pulse-echo inspection of carbon fibre plastics |

| AITM 6-4010 | Inspection of fibre composites by ultrasonic phased array technique |

Aeronautical qualified stamping & ultrasonic control

As a professional expert in aeronautical stamping and ultrasonic control, DEMGY is qualified to produce all your aeronautical parts. These parts must meet specific specifications and respect numerous conditions to maintain a perfect fit during their entire period of use. This is the reason why DEMGY passes each of them to the ultrasonic control.

In order to arrive at a material adapted to the aeronautical sector and capable of passing the ultrasonic test, DEMGY examines numerous configurations beforehand, such as the thickness of the plate, the stacking sequence or the radius of the tool.

Each part then has its own manufacturing parameters:

- Holding time,

- Holding temperature,

- Stamping pressure.

Finally, each part is tested and verified according to the following criteria:

- Elastic return and final angle measurement,

- Porosity rate,

- Degree of crystallinity,

- Thickness variation,

- Flexibility,

- Resistance,

- Curvature...

Airbus qualified stamping

Our stamping line is qualified by Airbus, specified AIPI (Airbus Process Instruction) and AIPS (Airbus Process Specification), for PEEK/CF (laminate composed of PolyEtherEtherKetone resin reinforced with continuous carbon fibers), PPS/C (laminate composed of PolyPhenylene Sulfide resin reinforced with continuous carbon fibers) and PPS/GF (laminate composed of PolyPhenylene Sulfide resin and reinforced with continuous carbon fibers) To test them, we use ultrasonic inspection means (NDT) also certified by Airbus (A-scan and C-scan).

The materials supplied have enabled Airbus to streamline the production of its aircraft and to gain in lightness, performance and durability. With increasingly competitive machines, DEMGY has taken the gamble of investing in advanced production lines and technologies, giving pride of place to development and responsiveness. Today, we are proud to be one of the first suppliers of the leading aeronautics company.

DEMGY's added value in the stamping of plastic composites

Today, the aerospace industry requires increased speed and productivity, thanks to the evolution of mobility worldwide. In spite of the control and qualification required to manufacture aerospace parts, DEMGY has developed its stamping technology in an optimal way, thus respecting the rigorous production rate of the industry. The materials produced are thus manufactured in an unbeatable time and at a controlled cost.

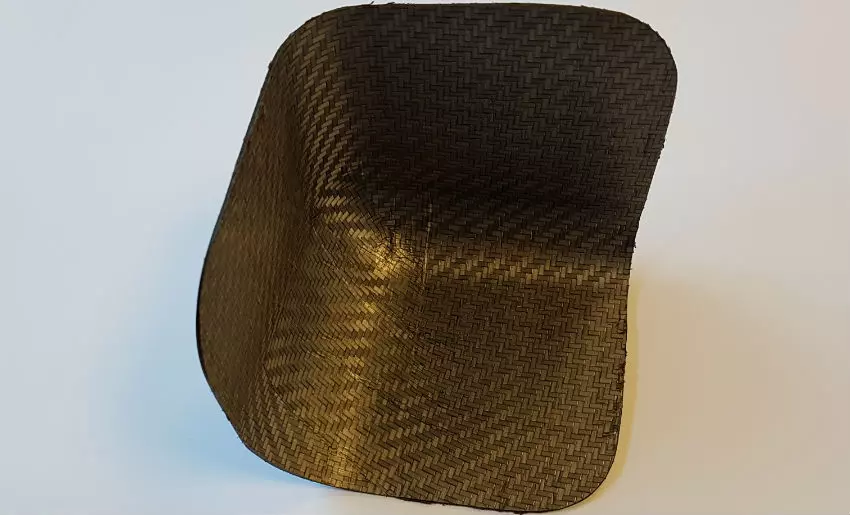

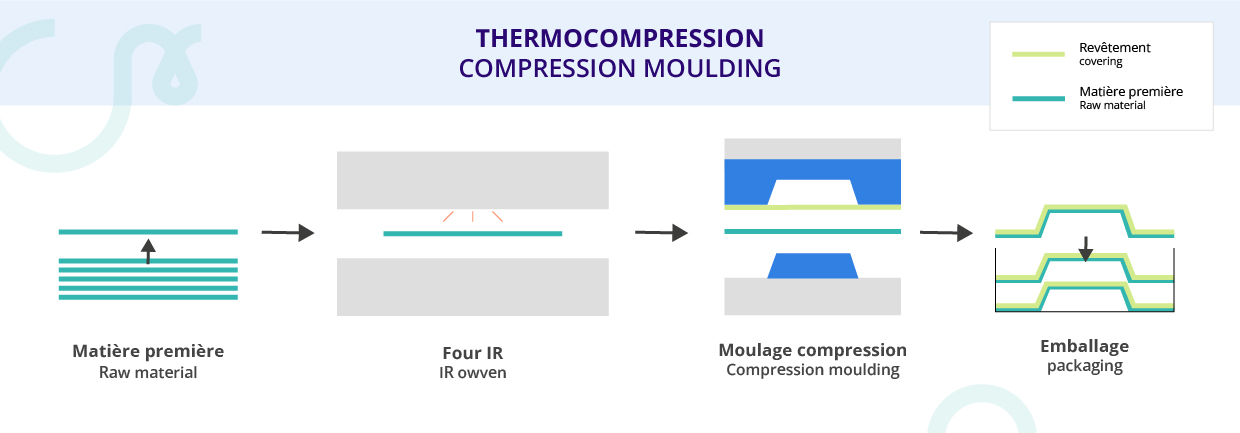

Thermocompression of composite fabrics or preforms

Thermocompression is a technology that allows you to form parts from unconsolidated (powdered or comelted) composite fabrics. You get appearance or structural parts in one step, without the need to manufacture consolidated plates in the first step. This manufacturing process is usually used for complex shapes where stamping is not possible.

To reduce cycle times and gain productivity, DEMGY can use Roctool technologies, supplier of manufacturing solutions adapted to plastic injection and composite molding. DEMGY and Roctool work closely together to optimize energy consumption and control machine investments. Two adapted induction heating technologies are used in our manufacturing workshops:

- The 3iTech® (Integrated Internal Induction Technologies): a technology that allows to heat the molding surfaces very quickly, by integrating a mass heating in a steel tooling... Through precise design of the tools (positioning of the water and induction circuits), it is possible to achieve optimum levels of consolidation of the composite fabrics and therefore optimum performance for the final part. The Group has five single-zone and dual-zone generators of up to 300 kW.

- The LIT™ (Light Induction Tooling) process enables tooling costs to be controlled by dissociating heating/cooling platens and molds to the shape of the part. The Group uses this principle for the sports & leisure or cosmetics fields.

The main advantage of these two technologies? Thanks to the innovative Heat & Cool process., molding can be done very quickly with a single-zone or dual-zone induction generator, which allows you to gain in productivity and competitiveness. Roctool's induction heating technology also allows :

- Achieve texture sets with a footprint replication rate of nearly 90% (where conventional technology stops at 50%),

- To remove surface defects from an injected part while providing a very clean and aesthetic finish,

- To facilitate the filling of an impression,

- Reduce material thicknesses, especially for high-temperature polymers, as well as cycle times for the processing of thermoplastic composites,

- Fine control of the temperature field on the surface of the cavity, thus enabling the shaping of complex parts, including those of varying thicknesses

- Energy savings due to short cycle times

Roctool technology is particularly well suited to the needs and expectations of the aeronautical, aerospace and automotive industries. The quality of its finish makes it ideal for use in the cosmetics, luxury goods and luggage industries.

By combining Roctool technology and thermocompression of plastics or composites, DEMGY is able to perfectly replicate the surface of the mold, however complex, but also to faithfully imitate the finish of natural materials. Thanks to laser cutting, it is also possible to cauterize the edges to offer you a rendering that perfectly meets your expectations.

DEMGY offers you its expertise in thermocompression of composites or plastics. We can also manufacture flexible membranes, whose role is to ensure a perfect consolidation of the composite, whatever the shape of the part, even in undercut areas or right angles. Do not hesitate to contact us for more information !

Hybrid process

DEMGY is also able to manufacture your parts in a hybrid way. This technique consists in stamping a thermoplastic composite blank, then overmolding it and functionalizing it (fastener, screw, rib, assembly function...) by plastic injection.*

This process originated in the automotive industry, where productivity plays a key role. This manufacturing technique was then adapted and improved to ensure optimal consolidation of the thermoplastic composite, as well as to offer infinite qualitative finishing possibilities, which plastic injection allows.

This method of making a hybrid composite has many advantages :

● Only one tool is used, so a part is made in one step, which represents a considerable saving of resources

● This process hybridization is fast: the automotive-type cycle time lasts from less than a minute to a few minutes depending on the size of the part. This manufacturing process is adapted to high production rates

● Hybrid manufacturing of thermoplastic composites makes it possible to combine aesthetics and mechanics.

● No waste is created: no material is lost during the process.

● By using a hybrid composite process to manufacture complex parts, you avoid intermediate steps such as machining.

● Finally, DEMGY is able to apply this hybrid process to vegetable fibers, which are more sensitive to temperature and heating techniques.

Want to know more about hybrid thermoplastic composites? DEMGY offers you efficient and value-creating solutions, even for the most complex parts. Do not hesitate to contact our experts to learn more.