Flaxcomp®, the first 100% recyclable Bio Composite

DEMGY AtlantiqueFlaxcomp® is an eco-innovation

Flaxcomp® is the result of a partnership between two companies to build the first 100% recyclable bio-composite: DEMGY and Terre de Lin, an expert cooperative and world leader in the production of linen and reinforcements for parts applications Linen composites.

Good to know ! Normandy is the world's leading producer of quality flax (50% of production), thanks to the know-how of its farmers and its climatic conditions. Norman linen fiber is considered the best in the world. In recent years, "technical" flax has become a substitute for glass or carbon fibers used in composite materials, offering considerable weight gain and ensuring authentic biodegradability.

Flaxcomp® was developed and industrialized by DEMGY in partnership with Terre de Lin, a 100% French production chain. This cooperative has recently diversified into a composite fabric for composites in order to

manufacture pieces from the fabric. woven linen with bio-composite or high- performance composite fibers.

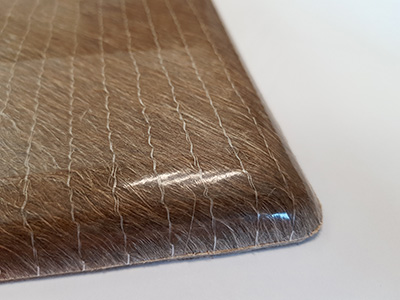

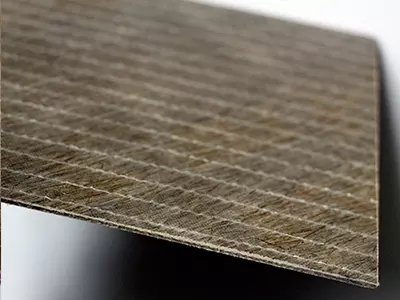

FLAXCOMP® combines flax fiber and cornstarch resin to create a 100% recyclable composite.

FLAXCOMP® is used to transform fibers into calendered or compressed panels or plates of fabrics or parts, depending on demand.

Flaxcomp®, a biobased composite, offers many disruptive advantages:

- 3E: Eco-sustainable, Eco-Design, Eco-Recyclable,

- The lightness (weight reduction but also manageability of the product, ease of use limiting the risk of MSDs - musculoskeletal disorders),

- Damping capacities for vibrations (acoustic, phonic) and shocks,

- Completely customizable aesthetics.

It is part of the demand for natural products, in keeping with the spirit of sustainable development and respect for the quality of ambient air in enclosed environments (interior of aircraft, automobile, habitat ...).

Flaxcomp® is suitable for all economic sectors.

It is a real breakthrough material, destined to take an increasingly important place in the manufacture of parts, subassemblies and products.

These products are used for semi-structural and cosmetic applications with industrial thermocompression, stamping and machining processes in the industrial, transport, luxury, sport and leisure, and home sectors. and many others. FLAXCOMP® is a range of thermoplastic composites based on flax fiber, which offers performance comparable to glass composites with exceptional vibration characteristics and a positive carbon balance.

FLAXCOMP® adapts to all your needs

| FABRICS | |

|---|---|

| MULTIAXIAL | UNI-DIRECTIONAL |

| Bi Axial 2*45° - 250g/m² | UD Flax 0° - 200g/m² |

| Bi Axial 2*45° - 350g/m² | UD Flax 90° - 200g/m² |

| BI Axial 2*45° - 400g/m² | UD Flax / Carbone 90° - 200g/m² |

| Bi Axial 2*45° - 500g/m² | |

| Bi Axial 2*45° - 600g/m² | |

| POLYMERES | |

|---|---|

| BLENDED | POWDERED |

| PP | PP |

| PLA | PLA |

| PA 11 | PA 11 |

| PA 12 | PA 12 |

| PCL | |

| EPOXY | |

The key benefits of FLAXCOMP®

- Good stiffness, flexural strength, fatigue and impact,

- Absorption of vibratory stresses (acoustic, phonic, shock, damping),

- Lightness, weight reduction,

- Natural and renewable resources, low carbon footprint, traditional processes,

- Customizable design on demand.