DEMGY Chicago

Aerospace MedicalDEMGY Chicago (formerly Met2plastic) is a metal to plastic solutions® provider specialized in thermoplastic injection molding, as well as the design and manufacture of its own molds. We cater to original equipment manufacturers, predominantly in the medical, aerospace, and industrial sectors.

We manufacture high-end parts in large or small quantities, from simple components to highly complex assemblies, made to customer requirements. With our vast expertise in this field, combined with the latest state-of-the-art machines and technology, we are able to produce high-quality parts with speed.

We are conveniently located in the Northwest Chicagoland suburb of Elk Grove Village, Illinois, just a 15 minute drive from Chicago O'hare airport, and less than a day's drive from Midwestern U.S states, including Indiana, Iowa, Michigan, Minnesota, Missouri, and Ohio.

Best Place to Work 2025

Best Place to Work 2025

Demgy Chicago has been awarded the “Plastics News Best Place to Work 2025” certification, in recognition of its corporate culture and the commitment of its teams.

Discover our expertises and our technologies

Did you know that DEMGY Chicago offers no less than 17 technologies related to 5 different areas of expertise? You can find details of these below.

|

Injection |

Machining |

Tooling |

Metallization & decoration |

Inspection, testing & analysis |

|---|---|---|---|---|

| Thermoplastic Injection molding | Machining of technical polymers | Co-design of components and parts | Manual and automated assembly | CMM Inspection |

| Thermoplastic - Injection molding in ISO class 8 (class 100,000) clean room | Machining of HPP (High Performance Plastic) polymers | Co-design and manufacture of sub-assemblies | Ultrasonic welding and assembly | Optical inspection equipment |

| Gas assist and structural foam molding | Design of molds and tooling | Color analysis with Color Spectraphotometer Material verification with Melt Flow Rheometer | ||

| Moldflow study | ||||

| Overmolding of inserts | Tooling manufacture |

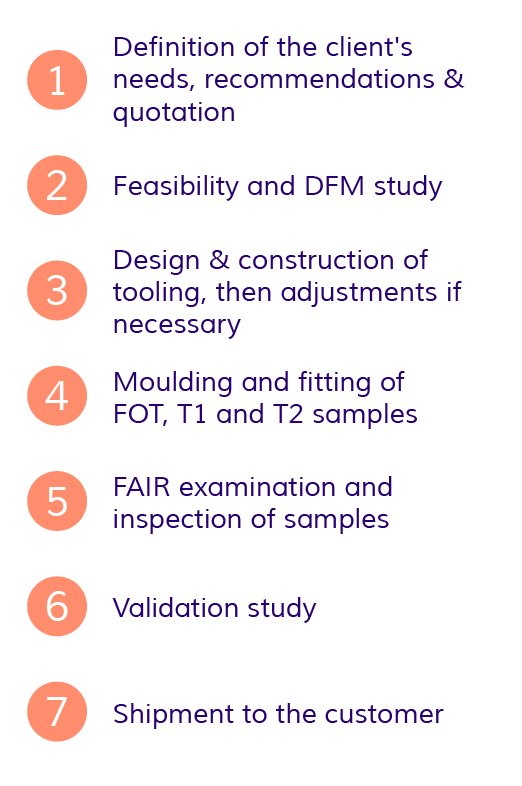

DEMGY Chicago is at your disposal for the duration of your project. From launch, mold building and production, right through to its completion, our multi-functional teams will work diligently on your project to ensure you receive high-quality service!

Your most complex projects, we realize them

DEMGY Chicago : Expert in the Medical and Aerospace industry

Medical industry

Specialist in the design and manufacture of high-performance plastic injection molded components for medical devices.

In the medical device sector, DEMGY Chicago stands out as a partner of choice for the production of complex, high-quality medical components. Thanks to its expertise in thermoplastic injection molding, CNC machining and assembly, as well as ISO class 8 cleanroom manufacturing capability in two cleanrooms, DEMGY Chicago offers complete solutions to medical equipment manufacturers.

Do you have a medical project in mind ?

Cleanroom medical device production and plastic injection expertise

DEMGY Chicago is equipped with two ISO class 8 cleanrooms, essential to meet the

strict cleanliness requirements of the medical industry, particularly for medical devices. This type of component requires a controlled environment to ensure contamination-free manufacturing, which is essential to meet hygiene and regulatory requirments. In addition to cleanroom manufacturing capability, DEMGY Chicago offers advanced techniques such as multi-component molding and gas-assisted molding. This enables the creation of complex components that combine precision and durability, meeting the specific needs of medical equipment manufacturers.

Complete production solutions: CNC machining, assembly and quality testing

In addition to plastic injection molding, DEMGY Chicago offers a full range of manufacturing services for medical devices, including CNC machining, ultrasonic welding assembly and finished product testing. These processes, combined with expertise in cleanroom molding of plastic parts, make DEMGY Chicago a preferred partner for customers requiring solutions that go beyond simple production.

DEMGY Chicago, your partner for the medical devices of today and tomorrow.

Our added value lies in our ability to produce complex medical sub-assemblies with high precision and in compliance with regulatory standards, including IQ/OQ/PQ validation. Our technical processing capabilities include in-mold pressure sensing, automated part inspection, and hands-free packing to ensure 100% part quality.

ISO 13485 certification

When it comes to medical devices, compliance with quality standards is crucial. DEMGY Chicago is ISO 13485 certified, guaranteeing our customers rigorously controlled manufacturing processes that comply with the regulatory requirements of the medical industry. We apply validation procedures (IQ/OQ/PQ) to guarantee the quality of every part produced, which is essential for medical devices such as MRI control interfaces and endoscopy components. This rigor in documentation and validation is an asset for customers looking for reliability and precision.

Technical expertise and strategic positioning in the medical market

DEMGY Chicago is proud to collaborate with leading companies in the medical sector. Thanks to our skills in multi-component plastic injection and high-performance production, we are a preferred choice for OEMs and subcontractors looking for cleanroom injection molding solutions. Our assembly capabilities and expertise in the development of complex medical components enable us to meet the most demanding requirements, particularly for medical devices requiring high performance thermoplastic materials that are suitable for sterilization and autoclaving applications, such as PEI, PPSU, and PEEK

New-generation medical devices thanks to our Group R&D centers

As a key industrial partner in the production of next-generation medical devices, DEMGY Chicago is constantly innovating to keep pace with developments in the medical sector. Our products, used in medical devices ranging from surgical devices to hospital beds and MRI machines, sdemonstrate our commitment to advanced medical solutions. With our expertise in injection molding of complex components and technology integration, we are perfectly positioned to support our customers in this transformation.

As a key industrial partner in the production of next-generation medical devices, DEMGY Chicago is constantly innovating to keep pace with developments in the medical sector. Our products, used in medical devices ranging from surgical devices to hospital beds and MRI machines, sdemonstrate our commitment to advanced medical solutions. With our expertise in injection molding of complex components and technology integration, we are perfectly positioned to support our customers in this transformation.

DEMGY Chicago, a trusted partner in the medical sector

DEMGY Chicago stands out in the medical sector for its complete solutions in medical device production. Our advanced infrastructures, rigorous quality standards and ability to produce high-precision components position us as a benchmark player for medical device manufacturers. Thanks to our ISO class 8 cleanrooms and ISO 13485 certification, we ensure that our customers receive secure solutions that comply with the most stringent standards.

Our added value:

- Injection mold and assemble medical device components in cleanrooms

- Respond rapidly to your calls for projects and adapt our production lines.

- Enhance the security and transparency of our processes by offering full traceability.

- Optimize performance and quality.

Would you like to tell us about your medical project ?

Aerospace industry

DEMGY Chicago: Molding Expertise for the Aerospace Industry

As the partner of choice for the aerospace industry, DEMGY Chicago stands out for its unrivalled mastery of high-performance thermoplastic injection molding. Our expertise is underpinned by our certification to AS 9100, a global benchmark for quality management and risk control in the aerospace industry. This certification attests to our commitment to offering robust solutions, combining reliability and high repeatability in all our processes.

An aerospace project ? Tell us more

DEMGY Chicago, a circular Multiplasturgy® offering

DEMGY Chicago offers much more than molding, thanks to advanced and diversified capabilities such as :

- High-precision injection molding

- Processing of high-performance thermoplastic materials

- Painting, decorating and assembly

- CNC machining

- Expertise in mold making

- Expertise in aerospace applications and documentation requirements

Our experienced teams are equipped to handle the design and manufacture of complex components that meet the most demanding performance and safety requirements.

Our Quality and Performance advantages

We understand that every part produced must be perfect: the slightest deviation can  have critical consequences in an industry where safety is paramount. Through a rigorous process of risk management, continuous improvement and documentation, we ensure impeccable quality at every stage of production, from initial molding to final assembly.

have critical consequences in an industry where safety is paramount. Through a rigorous process of risk management, continuous improvement and documentation, we ensure impeccable quality at every stage of production, from initial molding to final assembly.

Our approach, reinforced by cutting-edge technologies and multi-functional expertise, sets us apart from traditional molding companies, enabling us to deliver uncompromising, tailor-made solutions for the most demanding sectors.

With our advanced processing skills and state-of-the-art equipment, we have built our reputation on being able to take on highly technical, demanding applications, ensuring our customers’ success with mission critical projects.

- Wide range of high-performance materials: aerospace components

- Lightweight, high-strength materials

- Uncompromising precision and accuracy

- Affordable cost

- Customized finishes